Rail Type Platinum Thermal Resistance Collector

8 AD acquisition channels, which can be connected to multiple temperature measuring resistors at the same time.

The AD sampling rate is fast and the precision is high.

Support rail fixing method, easy and flexible installation.

Use the standard MODBUS protocol output, which is convenient for engineering networking and industrial applications.

Power supply anti-reverse protection design, wiring more assured.

Constant current control, low power consumption design, long service life.

Multiple indicator lights, the running status is clear at a glance.

Using industrial grade chips, built-in watchdog, stable and reliable operation.

- 产品描述

- Product Description

- Roduct Parameters

- Specifications

- Instructions For Use

-

8 AD acquisition channels, which can be connected to multiple temperature measuring resistors at the same time.

The AD sampling rate is fast and the precision is high.

Support rail fixing method, easy and flexible installation.

Use the standard MODBUS protocol output, which is convenient for engineering networking and industrial applications.

Power supply anti-reverse protection design, wiring more assured.

Constant current control, low power consumption design, long service life.

Multiple indicator lights, the running status is clear at a glance.

Using industrial grade chips, built-in watchdog, stable and reliable operation. -

HYHT208 is a high-performance, high-sensitivity temperature data acquisition terminal with 8-channel AD acquisition ports, which can be connected to PT100/PT1000 thermal resistance sensor signal input, converted into temperature data and output by the standard MODBUS protocol widely used in the industry , which is convenient for engineering networking and industrial applications, and supports secondary development. Support communication with the host computer by RS485 or LORA communication, and quickly set up a temperature measurement system.

HYHT208 is a high-performance, high-sensitivity temperature data acquisition terminal with 8-channel AD acquisition ports, which can be connected to PT100/PT1000 thermal resistance sensor signal input, converted into temperature data and output by the standard MODBUS protocol widely used in the industry , which is convenient for engineering networking and industrial applications, and supports secondary development. Support communication with the host computer by RS485 or LORA communication, and quickly set up a temperature measurement system. -

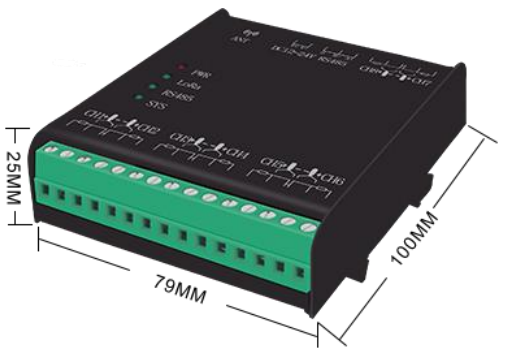

Product Size Description

Size: 79*100*25(mm)

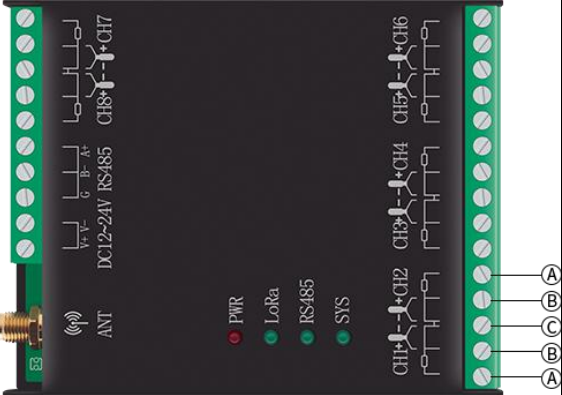

Product Interface Description

1、DC12V

-

V+: The positive pole of the power supply.

V+: The positive pole of the power supply. -

V-: The negative pole of the power supply

V-: The negative pole of the power supply

2、RS485

-

A+: RS485 positive

A+: RS485 positive -

B- :RS485 negative pole.

B- :RS485 negative pole. -

G :Ground wire.

G :Ground wire.

3、CH1—CH2

-

A :Connect to a line of different colors of the resistance sensor.

A :Connect to a line of different colors of the resistance sensor. -

B :Connect to one of the two wires of the same color of the resistive sensor.

B :Connect to one of the two wires of the same color of the resistive sensor. -

C :Connect to the other wire of the same color of the resistance sensor; if two sensors are connected at the same time, this interface is connected to a wire of the same color of the two sensors

C :Connect to the other wire of the same color of the resistance sensor; if two sensors are connected at the same time, this interface is connected to a wire of the same color of the two sensors

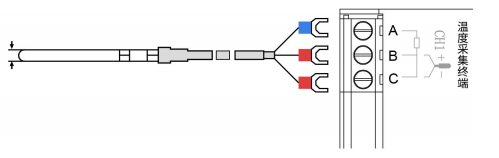

4、CH1

-

A :Connect a line of different colors to the resistance sensor.

A :Connect a line of different colors to the resistance sensor. -

B :Connect to one of the two wires of the same color of the resistance sensor.

B :Connect to one of the two wires of the same color of the resistance sensor. -

C :Connect to the other of the two wires of the same color of the resistive sensor.

C :Connect to the other of the two wires of the same color of the resistive sensor.

5、PT100/PT1000 Wiring Diagram

-

-

Specifications

Parameters

Interface

1 RS485 port, 1 power port, 8 differential ADC input channels

Operating Voltage

DC12V~24V

Working temperature

-10~60℃

Working humidity

<85%RH (no condensation)

Input signal

PT100/PT1000

Accuracy class

0.1% FS (excluding lead error)

Sampling frequency

32HZ

Resolution

0.1℃

Protection level

Power interface polarity protection, input channel optoelectronic isolation

RS485

Standard MODBUS protocol, baud rate 9600, 8 data bits, 1 stop bit, no parity

Installation method

Standard 35mm U-shaped rail mounting, wall mounting

-

Instructions For Use

Instructions For UseAfter the device is installed, it can work normally when powered on.

Instructions For UseAfter the device is installed, it can work normally when powered on.Protocol Description

The device supports the "MODBUS protocol", please contact our staff for the specific protocol

Disclaimer OF Warranties

The company reserves the right to change this specification and update the product. The specification and product may be updated without prior notice without affecting the product quality and user usage. We are not responsible for any direct, indirect, intentional or unintentional damage and hidden dangers caused by improper use and out-of-specification use.

Sample Request